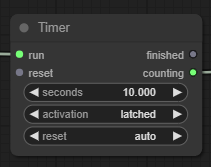

Timer Node

This node acts as a timer. It's often used to give your measurements time to stabilise after a change in how your machinery is operating.

This node is used in all modules and is one of the timing nodes.

The way this node operates has a lot to do with its options - a more detailed explaination of how you can use Timer nodes is shown further below.

Inputs

Run (Input #1) is a boolean value that is used to start the timer. It's behaviour is changed by the activation option.

Reset (Input #2) is a boolean that is used to reset/stop the timer.

Outputs

Finished (Output #1) is true if the time chosen in the seconds option has elapsed.

Counting (Output #2) is true if the timer has started, but not yet elapsed.

Options

Seconds determines how many seconds the timer should run for before the ''Finished“ output turns on.

Activation determines how the clock is started.

If Activation is Instant, the 'run' input needs to remain true for the entire amount of time. If the option is Latched, the input only needs to be on for a moment - the timer will continue to count even if the run input them drops back to false.

Reset determines how the timer is reset back to its starting state, ready to count down again.

If Reset is manual, the Finished output will remain on until the Reset input is triggered. If the mode is auto, the Finished output will only be true for one second, after which the timer will automatically reset.

Note that timers are cumulative until reset, which means that if you have a 10 second timer and do the following…

- Turn 'run' on for 4 seconds

- Turn 'run' off for 1 minute

- Turn 'run' on back on

Then the timer will trigger six seconds after you turn it back on, unless you've told it to reset. This is because it already counted the 4 seconds from the earlier, cancelled attempt.

An easy way to ensure you could 10 seconds every time is to connect the reset input to the Not of the run input.

Examples

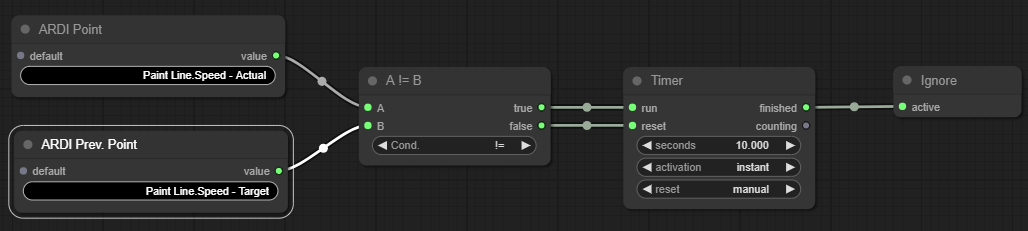

This logic will trigger something if the Paint Line Actual Speed has been different from the Paint Line Target Speed for more than 10 seconds.

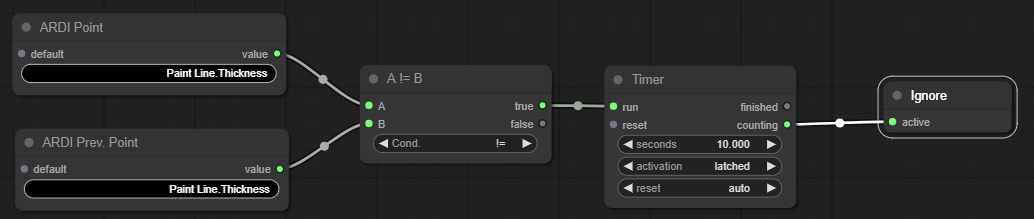

This logic will ignore events that happen in the ten seconds after the thickness of the product changes.

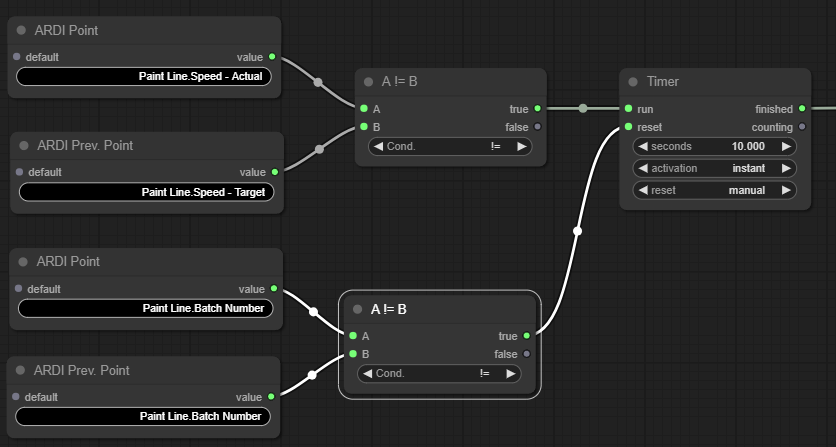

This logic will flag any batches you've produced where the actual line speed and the target line speed were different for more than 10 seconds in total.